Customer first, quality foremost.

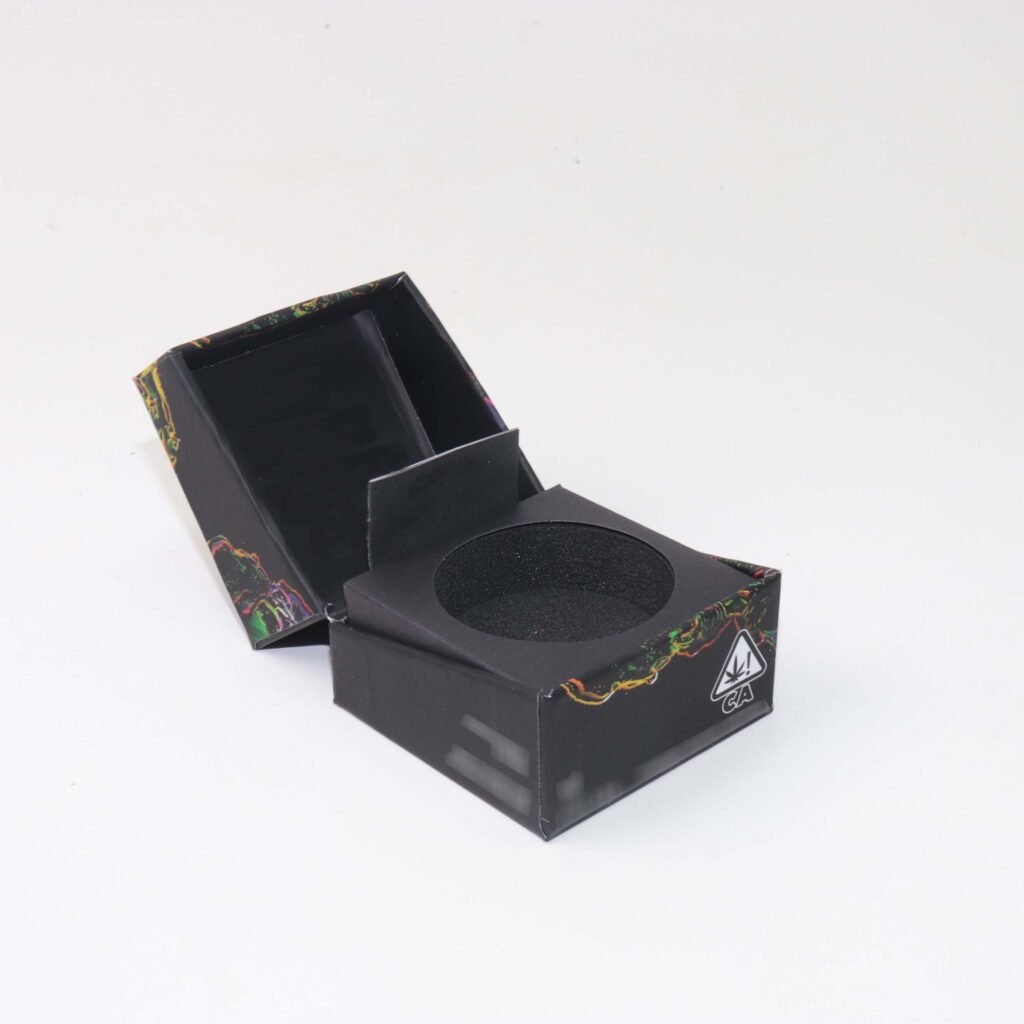

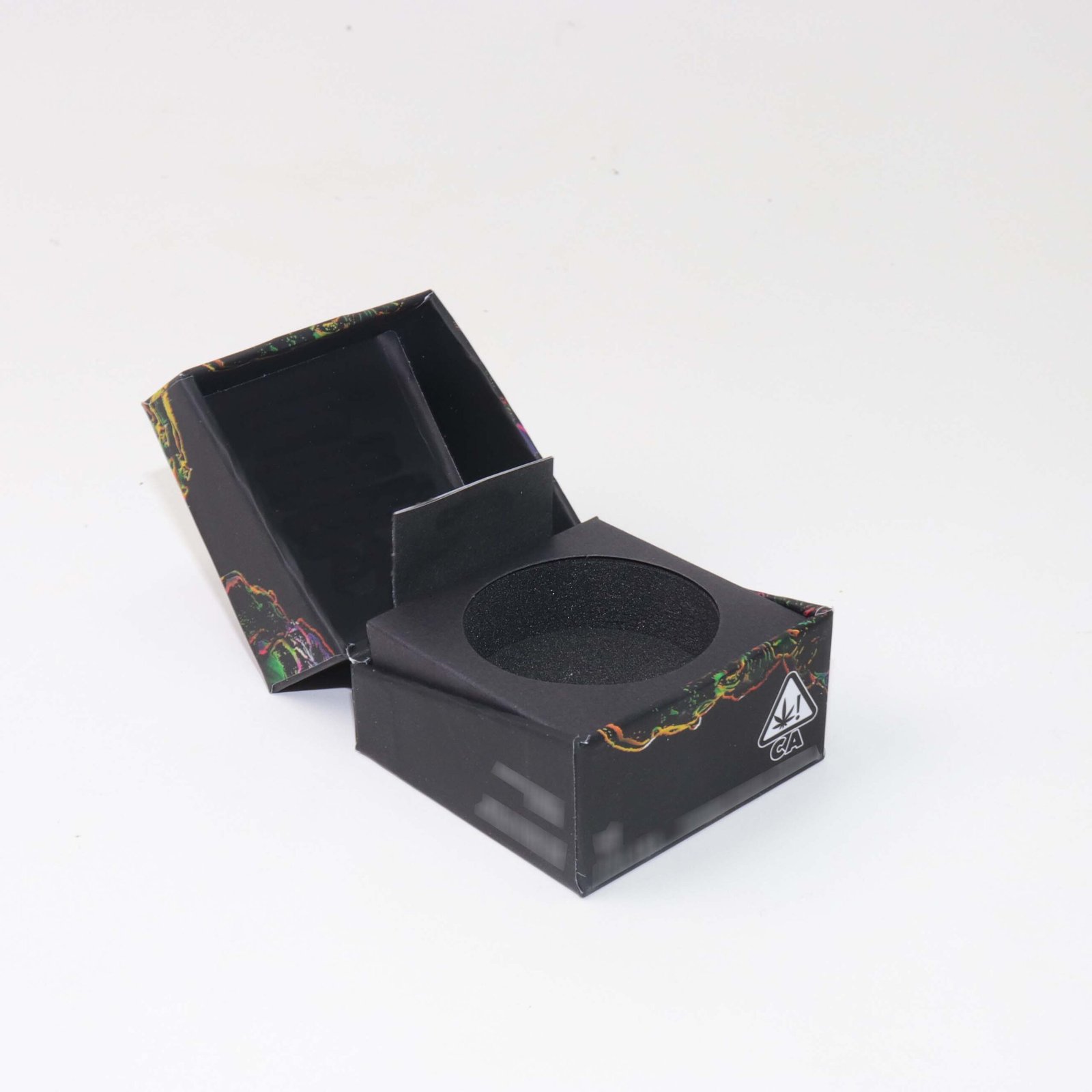

Childproof Drawer Box for Color Atomizers, Vapes and Mini Perfumes

The Color Atomizer Childproof Buckle Drawer Box is designed for brands that need both premium presentation and reliable protection. The rigid drawer structure combined with a child-resistant buckle keeps your color atomizers, vape cartridges or mini perfume vials securely locked in place, while still offering a smooth, elegant unboxing experience for adults.

Made from thick rigid paperboard (1000–1200 gsm) wrapped in colored specialty paper, this box feels substantial in the hand and looks refined on any retail shelf or display. The inner tray can be customized in foam, EVA or blister to match your exact bottle or cartridge size, giving your products a snug, stable fit during transport and daily use.

Every surface of the box can be fully customized with your brand elements: CMYK or Pantone printing, hot foil stamping, spot UV, embossing/debossing, matte or glossy lamination and more. Whether you are launching a new vape line, upgrading your perfume gift set or creating a limited-edition collection, Chengyi Packaging helps you turn this childproof drawer box into a strong part of your brand story.

Why Choose This Box for Your Vape or Perfume Brand?

Compared with standard folding cartons, this childproof buckle drawer box gives your vape oil, disposable vapes or travel-size perfumes a much more premium, gift-ready look. The rigid structure and child-resistant closure help you meet safety expectations in many markets, while still allowing adults to open the box easily and intuitively.

- Stronger brand impact: Large printable areas for bold colors, metallic foils and clear logos that stand out online and in store.

- Child-resistant structure: Drawer box with secure buckle to reduce accidental opening by children and add perceived value to your packaging.

- Custom-fit inserts: Foam, EVA or blister trays tailored to your atomizer, cartridge or mini perfume vial for better protection and display.

- Flexible MOQ & fast lead time: Suitable for new product launches, small batches and growing vape or fragrance brands.

Share your box size, bottle or cartridge dimensions, artwork and order quantity with our team, and we will recommend a suitable structure and finishing solution, then prepare a sample for you to verify the look, fit and childproof performance before mass production.

| Why choose us Services We Provide |

| Competitice price ·Factory price. Advanced Printing Machine. | Sample Servive ·Fast reply. Making mock up sample for 1-3 days. Artwork design to confirmation with you. | Production Quality ·Third-party Inspection. ·QC inspection. Every step we will check again and again, high end quality and customer first are always our goals. |

| Logistic Sercice ·Sea and air and railway shipping. ·Express delivery. ·LCL FCL DDP service. We can offer logistic company service if you have not forwarder in China. | Customer Service ·Reply quickly within 4 hours. ·Consultant communication. We have experienced sales consultant service for you. | Total Packaging Solution ·Design-sample-bulk order-QC-packing-delivery. From design, sample, production, QC, packing, delivery, we will help you to solve it. |

Craft Display

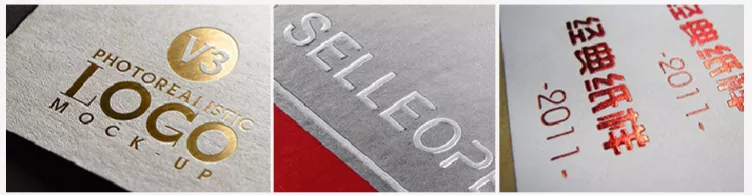

UV process

The colors are bright, fresh, layered, and aesthetically pleasing, with a strong sense of three dimensionality, mainly to increase the brightness and artistic effect of the product.

Hot stamping process

The characteristics of hot stamping are: prominent patterns, beautiful appearance, bright and eye-catching colors, wear resistance, and weather resistance. Hot stamping is a general term for a craft, which does not mean that it is golden when it is hot stamped. There are various types of gold, silver, laser gold, laser silver, black, red, green, and so on.

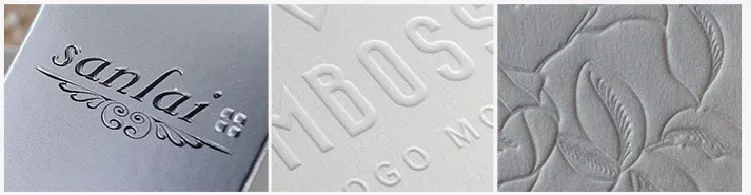

Concave convex process

The various concave convex images, graphics, and patterns produced by concave convex embossing display patterns of varying depths, giving a more pronounced relief effect and enhancing the sense of three dimensionality and artistic appeal

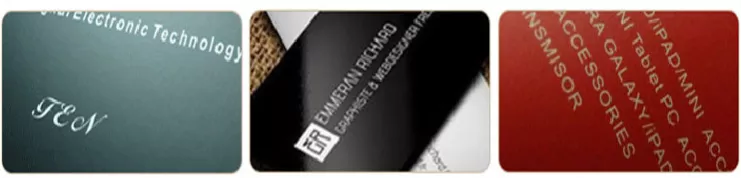

Film coating process

The laminating process is a surface processing technique after printing, which covers the surface of the printed product with a layer of transparent plastic film to form a paper plastic integrated processing technology. According to the process, it can be divided into two types: pre coated film and coated film, and the material can be divided into two types: glossy film and matte film.

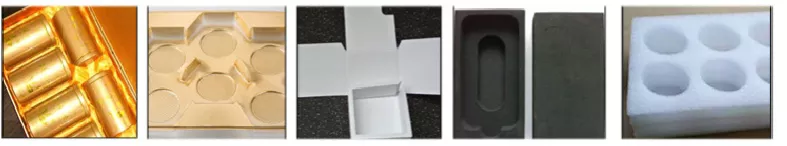

Commonly used inner tray

Silk fabric,

Blister inner tray,

Pit paper tray,

Black and white EVA,

Pearl cotton

How To Cooperation With Us?

Total packaging coopertation with chengyi packaging, tell you how to custom packaging with us.

1.Get quote

Send to quote to us, the details about MOQ, design, logo,size etc.

2.Design

Artwork design confirmation wirh us.(PDF,CDA etc.)

3.Making sample

To make sure product satisfied with you,we suggest that make a sample before bulk order production.

4.Production

Any details confirmation start to production.The time will bepends on your quantites,In generally 7-12days.

5.QC&Packing

Before delivery,our QC inspector or custimer will check the quality,no any problems will keep giing next process.

6.Delivery Service

We will confirm adderss with you again,if you have ne forwarder in China,we will help you find or offer you delivery service.

pricing for bulk orders, Contact us for samples or a quote now:

It's smart for you to source directly from a paper packaging manufacturer like us.e offer low MOQ, fast turnaroound, and, most important. competitive whole

Linkedin

Linkedin

Google +

Google +